Our commitment to sustainability

Elastoplast has you covered – so you can live a life uninterrupted. More than ever, the planet we live on needs our help. That’s why we are dedicated to continuously finding ways to lower our resource consumption, environmental impact, and carbon footprint. So that we can continue to have you covered for the next hundred years.

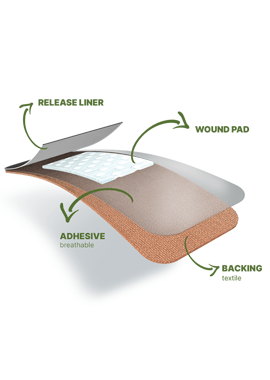

This focus on environmental sustainability has inspired us to continuously work to maximise the protection, performance, and efficacy of our portfolio while minimizing the impact it has on the environment. This motivates us to constantly examine the materials we use, as well as where we source them, to reduce their economic impact while adhering to our strict standards for quality and performance.

For more information about previous achievements in sustainability, please see our Commitment to Sustainability.